Some of the best foam manufacturers in the world

LONDON--(BUSINESS WIRE)--The rising demand for PU foams is one of the critical reasons that will drive polyurethane foam market growth in the coming years. PU foams are extensively used in industries like electrical and electronics, construction, consumer goods, healthcare, automotive, sports equipment, and furniture and bedding.

This is mainly because of the economic growth along with the growth of the automotive and packaging industries. Moreover, there is also an increase in the number of construction projects and this rise in construction of residential and office towers will subsequently boost the adoption of PU foams in various applications such as insulation, roofing, floor carpets, and sealants, driving market growth. Furthermore, this industry research report also presents a competitive analysis of the market by type (flexible PU foams, rigid PU foams, and molded PU foams) and application (furniture and bedding, building and construction, transport, appliances, and others) and geography (APAC, Europe, MEA, North America, and South America).

based foams are also preferred in the packaging industry as they help in the optimization of the production process.” says a senior analyst at Technavio.

Top five polyurethane foam market vendors

BASF SE

BASF SE operates in five segments, which include, agricultural solutions, chemicals, functional materials and solutions, performance products, and others. Its key offerings include PU foam. The company manufactures both spray PU foam under registered name COMFORT FOAM and rigid PU foams under registered names Autofroth and Autopour.

Covestro AG

Covestro AG runs its operations through four segments: polyurethanes; polycarbonates; coatings, adhesives, and specialties; and all other segments. The company manufactures PU foams, which are used in various industries, such as automotive, construction, and packaging.

Hong Kong Foam

HongKongFoam is one the most advanced foam & rubber producer in Hong Kong & China. The standards that we consider for our company is based on worldwide standards that are universally acceptable.

ISO, ASTM, and DIM are some of the standards which are exactly considered in our products. After the manufacturing process each product will be tested through our precise testing instruments and have to meet the requirements of our standards to become an industrial product.

Click to read more articles about the best foam suppliers in the world

DowDuPont

DowDuPont runs its operations through nine segments: agriculture; performance materials and coatings; industrial intermediates and infrastructure; packaging and specialty plastics; electronics and imaging; nutrition and biosciences; transportation and advanced polymers; safety and construction; and corporate. The company manufactures PU foams under the brand name DELTA THERM and BETAFOAM.

Huntsman International LLC

Huntsman International LLC runs its operations through five segments: advanced materials, performance products, polyurethanes, textile effects, and corporate and eliminations. The company offers various types of PU foams such as viscoelastic PU foams, high resilience PU foams, microcellular PU foams, and spray PU foams.

Recticel NV

Recticel NV runs its operations through four segments: flexible foams, bedding, automotive, and insulation. The company manufactures PU foams under the brand name KAPUA mattress foams.

Looking for more information on this market? Request a free sample report

Technavio’s sample reports are free of charge and contain multiple sections of the report, including the market size and forecast, drivers, challenges, trends, and more.

Browse Related Reports:

Global Industrial Wax Market 2019-2023 - The market research study identifies BASF SE, Exxon Mobil Corp., Numaligarh Refinery Ltd., PJSC LUKOIL, and Sasol Ltd., as the leading players in the global industrial wax market.

Global Glycol Ethers Market 2019-2023 - The market research study identifies BASF SE, DowDuPont Inc., Eastman Chemical Co., LyondellBasell Industries Holdings BV, and Royal Dutch Shell Plc., as the leading players in the global glycol ethers market.

About Technavio

Technavio is a leading global technology research and advisory company. Their research and analysis focuses on emerging market trends and provides actionable insights to help businesses identify market opportunities and develop effective strategies to optimize their market positions.

With over 500 specialized analysts, Technavio’s report library consists of more than 10,000 reports and counting, covering 800 technologies, spanning across 50 countries. Their client base consists of enterprises of all sizes, including more than 100 Fortune 500 companies. This growing client base relies on Technavio’s comprehensive coverage, extensive research, and actionable market insights to identify opportunities in existing and potential markets and assess their competitive positions within changing market scenarios.

EPDM Closed Cell Foam

Fostek Corporation manufactures high quality plastic and rubber blended, closed and semi-closed cell foams in our continuous roll process as well as in custom profile shapes. Fostek has developed and produces our family of EPDM closed and semi-closed cell foams in our IATF 16949:2018 certified production facility in Bedford, Virginia.

EPDM Closed Cell foam

Fostek Corporation defines its EPDM closed cell family as foams, when tested to ASTM D1056 @ 25% compression deflection, results in a range of 13.8 kPa up to 89.6 kPa max. The corresponding psi (pounds per square inch) products are in the 2-5 psi; 5-9 psi; 9-13 psi; and 12-16 psi ranges.

Fostek’s point of difference encompasses choices of compression deflections to target specific applications and needs for our customers. Fostek can “tune in” its foams for new engineering and design challenges to deliver the desired performance.

What is EPDM Closed Cell Foam used for?

Closed-cell foams are utilized in many of the same applications as our semi-closed foams. Fostek’s EPDM closed cell foam delivers excellent performance and durability for a variety of applications. Our proprietary “family” of EPDM foam products are used in the automotive industry as well as in appliance, weather stripping, and general industrial uses for a variety of applications and can be either die cut or in custom profile form, often with PSA.

NVH (noise, vibration, & harshness) seals, gaskets, pads, closure strips, pillar stuffers, cushioning in or around windshields, door panels, instrument panels, headliners, etc.

Acoustic / sound control in or around windshields, door panels, instrument panels, headliners, etc. These are used alone or in composite to achieve STL (sound transmission loss) targets in a vehicle component “system”…i.e. a door “system” that includes the metal door, the glass, and the inner cabin door trim panel.

NOTE: In some systems, Fostek’s EPDM foam with skin 2 sides might be used at 5mm (+/-) as a functional acoustic/moisture control material.

HVAC seals and gaskets providing air and water sealing

APPLIANCES utilize these foams for the same performance reasons as listed above

Applications that need very good UV resistance and a wide operating temperature are excellent applications for our EPDM foams: weather stripping; construction seals; window glazing seals, etc. These are used in custom profile form as well as die cut and stripping.

More information about Fostek EPDM Closed Cell Foam

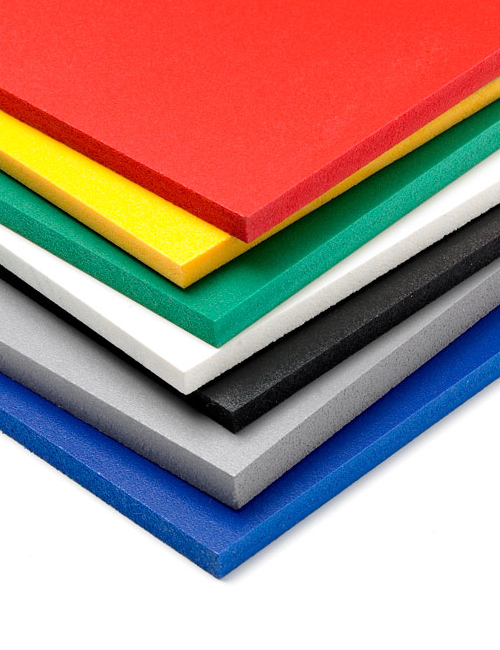

Fostek’s continuous roll technology produces EPDM closed cell foam rolls that range in gauge from 3mm thick to 32+ mm thick. We believe we have capability up to 38+mm, Fostek’s closed cell technology produces a consistent cell structure. Rolls are available in a variety of widths and lengths. The most common widths are a roll of a minimum width of 54 inches and a roll with a minimum width of 27 inches. Black is the most common color, however, we have also produced EPDM foam in a natural color. Other colors may be available based on minimum volume requirements. Depending on certain parameters, closed cell foams are available with skin-two-sides, skin-one-side, and no skin. The most common packaging for these products to adequately protect them during shipping and handling is to place them in boxes on skids.

For more information on Fostek’s EPDM closed cell foam, please contact our sales office at 574-284-1000 or click here to contact us and receive a prompt reply.

hongkongfoam

Foam is an object formed by trapping pockets of gas in a liquid or solid.

A bath sponge and the head on a glass of beer are examples of foams. In most foams, the volume of gas is large, with thin films of liquid or solid separating the regions of gas. Soap foams are also known as suds.

Learn more about joyce

Solid foams can be closed-cell or open-cell. In closed-cell foam, the gas forms discrete pockets, each completely surrounded by the solid material. In open-cell foam, gas pockets connect to each other. A bath sponge is an example of an open-cell foam: water easily flows through the entire structure, displacing the air. A camping mat is an example of a closed-cell foam: gas pockets are sealed from each other so the mat cannot soak up water.

Foams are examples of dispersed media. In general, gas is present, so it divides into gas bubbles of different sizes (i.e., the material is polydisperse)—separated by liquid regions that may form films, thinner and thinner when the liquid phase drains out of the system films.

When the principal scale is small, i.e., for a very fine foam, this dispersed medium can be considered a type of colloid.

Foam can also refer to something that is analogous to foam, such as quantum foam, polyurethane foam (foam rubber), XPS foam, polystyrene, phenolic, or many other manufactured foams.

Foam is an amazingly useful and versatile material that forms the basis of countless items that we see and use in everyday life.

Its applications range from tiny and intricate uses such as speaker filter foam, all the way up to large scale upholstery foam; there seems to be never ending variety to the applications and here at ACT Foam, we have a wide ranging stock of many different kinds of foam for sale.

Read on : China foam supplier

what is foam?

Thermoforming is a widely used process for the manufacture of foam sheet products. Polystyrene foam food trays for instance can be produced by first heating the thermoplastic foam sheet, causing the gas contained to build up pressure and expand, after which a vacuum pressure can be applied to draw the sheet in the required form on the mould.

This production method appears to be a very sensitive process with respect to e.g. the sheet temperature, the pressures applied and the cooling time.

More problems can be foreseen when for environmental reasons the blowing agent will be adapted (for instance replaced by a gas with a lower molecular weight). To gain more insight in the occuring phenomena the large deformations of a foam structure have been analysed using finite element modelling. To this end a constitutive model has to be defined.

Starting from the basic theory given by Gibson & Ashby [1], the behaviour of a closed cubic cell has been elaborated for large strains. The total stiffness is then the sum of the contributions of the edges and faces of the cell and the gas contained in it.

The large deformations cause anisotropy of the cells [2], which influences their tangential stiffness. The constitutive model developed here includes the effects of internal gas pressure and the evolving anisotropy.

Thermoforming is a widely used process for the manufacture of foam sheet products. Polystyrene foam food trays for instance can be produced by first heating the thermoplastic foam sheet, causing the gas contained to build up pressure and expand, after which a vacuum pressure can be applied to draw the sheet in the required form on the mould. This production method appears to be a very sensitive process with respect to e.g. the sheet temperature, the pressures applied and the cooling time. More problems can be foreseen when for environmental reasons the blowing agent will be adapted (for instance replaced by a gas with a lower molecular weight).

Click on the link to read what is foam article

To gain more insight in the occuring phenomena the large deformations of a foam structure have been analysed using finite element modelling. To this end a constitutive model has to be defined. Starting from the basic theory given by Gibson & Ashby [1], the behaviour of a closed cubic cell has been elaborated for large strains. The total stiffness is then the sum of the contributions of the edges and faces of the cell and the gas contained in it. The large deformations cause anisotropy of the cells [2], which influences their tangential stiffness. The constitutive model developed here includes the effects of internal gas pressure and the evolving anisotropy.

EPDM Closed Cell Foam

Fostek Corporation manufactures high quality plastic and rubber blended, closed and semi-closed cell foams in our continuous roll process as well as in custom profile shapes. Fostek has developed and produces our family of EPDM closed and semi-closed cell foams in our IATF 16949:2018 certified production facility in Bedford, Virginia.

EPDM Closed Cell foam

Fostek Corporation defines its EPDM closed cell family as foams, when tested to ASTM D1056 @ 25% compression deflection, results in a range of 13.8 kPa up to 89.6 kPa max. The corresponding psi (pounds per square inch) products are in the 2-5 psi; 5-9 psi; 9-13 psi; and 12-16 psi ranges.

Fostek’s point of difference encompasses choices of compression deflections to target specific applications and needs for our customers. Fostek can “tune in” its foams for new engineering and design challenges to deliver the desired performance.

What is EPDM Closed Cell Foam used for?

Closed-cell foams are utilized in many of the same applications as our semi-closed foams. Fostek’s EPDM closed cell foam delivers excellent performance and durability for a variety of applications. Our proprietary “family” of EPDM foam products are used in the automotive industry as well as in appliance, weather stripping, and general industrial uses for a variety of applications and can be either die cut or in custom profile form, often with PSA.

NVH (noise, vibration, & harshness) seals, gaskets, pads, closure strips, pillar stuffers, cushioning in or around windshields, door panels, instrument panels, headliners, etc.

Acoustic / sound control in or around windshields, door panels, instrument panels, headliners, etc. These are used alone or in composite to achieve STL (sound transmission loss) targets in a vehicle component “system”…i.e. a door “system” that includes the metal door, the glass, and the inner cabin door trim panel.

NOTE: In some systems, Fostek’s EPDM foam with skin 2 sides might be used at 5mm (+/-) as a functional acoustic/moisture control material.